CNPC POWDER, a renowned manufacturer of 3D printing metal powders in China, has been at the forefront of innovation and industrialization of micron and nanoscale metal powder materials. Our dedication to innovation and R&D has enabled us to offer a diverse range of metal powders, including aluminum base powder, titanium base powder, copper base powder, nickel base powder, iron base powder, and a comprehensive array of high-quality metal powders specifically designed for 3D printing. These powders are designed for use in a wide range of 3D printing technologies, such as SLS, SLM, Binder Jetting, EBM and LMD, as well as injection molding and powder metallurgy applications.

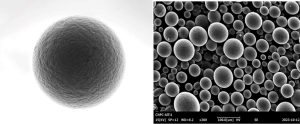

Our powders are highly regarded by customers due to the excellent sphericity, very low satellite powder content, and high powder rate. Moreover, CNPC POWDER is committed to sustainability and environmental protection. We continuously innovate in low-carbon, green, and recyclable materials and production processes to provide customers with not only high-quality but also cost-effective metal powders.

Our commitment to excellence and innovation is reflected in our certifications, including recycled titanium alloy SCS, ISO9001, ISO41001, ISO45001, IATF16949, ISO13485, and national hi-tech enterprise certification, as well as a number of patents for core technology invention and participates in national standard formulation such as aluminum alloy powder.

Our AM facility has been equipped with more than 10 lines which is equivalent to 3500 tons of atomized metal spherical powders under inert gas, and we plan to expand 10 more lines by the end of 2024. Focusing on the production of materials for our main OEM customers in Europe and America along with aerospace and medical parts producers. Meanwhile, we are expanding production to establish four workshops, including the establishment of a clean workshop to achieve 6S management.

Since its establishment, CNPC POWDER has always regarded it as its mission to promote the industrialization of 3D printing by reducing material costs. For many large-scale applications, titanium alloy powder is still a costly material. The powder manufacturing process from scrap recycling will greatly reduce the cost of powder materials for metal 3D printing without compromising the maximum required quality or reducing the application field, and as a green alternative to traditional titanium alloy powder sources, it offers more possibilities for expanding 3D printing application scenarios.

In September 2023, CNPC POWDER became the first 3D printing metal powder company in the domestic industry to obtain SCS certification for 100% titanium alloy recycled materials, and through a full analysis of the product’s life cycle, the carbon emissions of its production process are only 10% of the traditional EIGA production process. CNPC POWDER is now actively expanding its production capacity, and expects the annual production of Ti64 alloy powder to reach 360 tons by the end of 2024, a quantity that marks the largest supplier of recycled titanium alloy powder in the domestic market.

Over the past few years CNPC POWDER’s contributions have been, the development of even higher purity powders for variety of industries, development of a proprietary

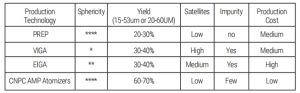

NanoPrint powder for customized AM processes. Now our next contribution is our AMP Production line for AM powders. CNPC POWDER’s AMP technology, when compared with the Plasma Rotating Electrode Pulverizing technology (PREP), the aluminum powder produced by AMP atomizers, has a better composition ratio, less gas consumption and lower cost while ensuring high sphericity. These advantages mean that our powder can provide customers with material that can satisfy more demanding requirements for AM grade aluminum alloys and other materials.

CNPC POWDER opened its doors in 1998 as a family business to service the growing domestic powder market. Over the years we have made our primary focus the development of materials that exceed client requirements for materials. This focus on exceeding expectation has given us the ability to produce an ever-expanding catalog of powders, and a depth and breadth of knowledge that our clients can leverage to improve their processes and improve their business. Today CNPC POWDER’s determination has allowed for the expansion our markets and has made us a key member of the powder production industry. CNPC POWDER has been able to forge new connections with North and South American powder users as well as a growing connection to Europe. As we develop new powders for advanced manufacturing like additive manufacturing, our new AM facilities and R&D Center will allow us to continuously support and innovate our industry.